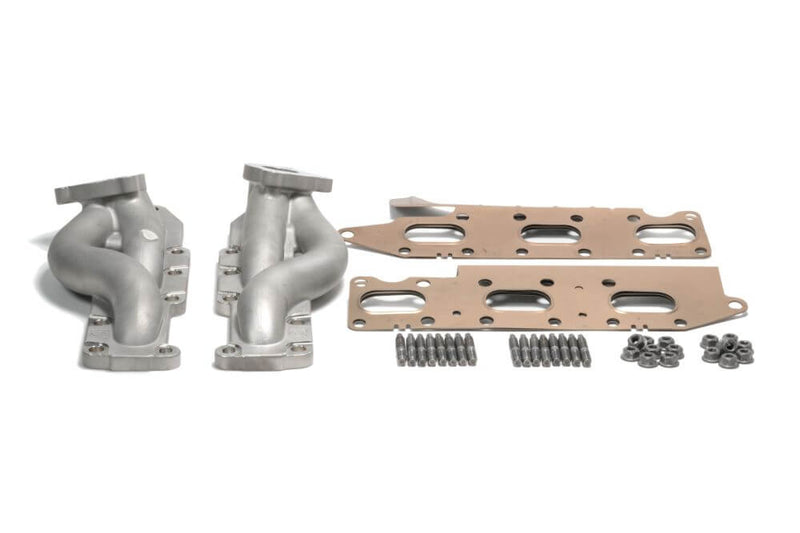

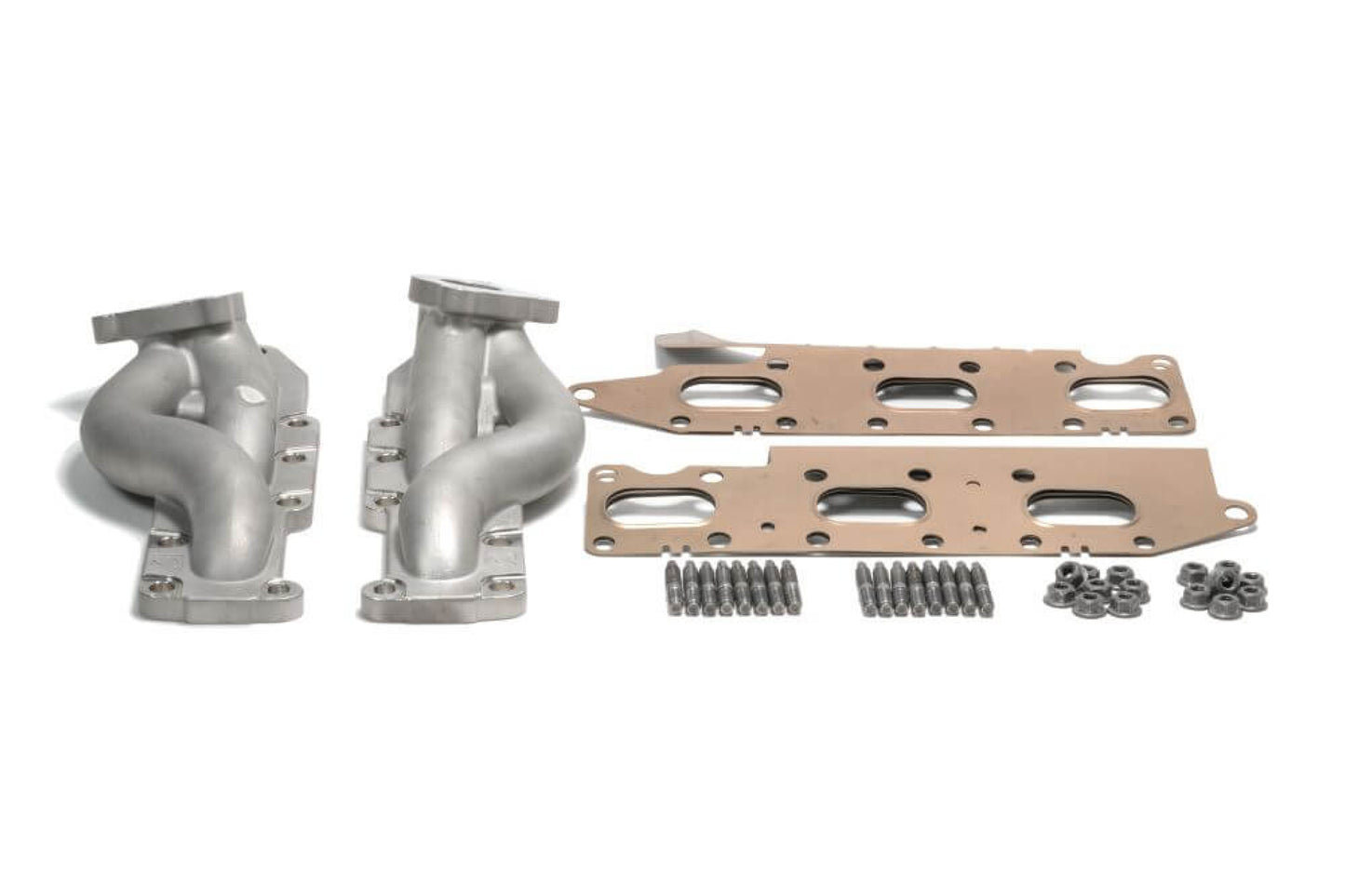

Full-Race 2011-2016 Ford F-150 3.5L Ecoboost Turbo Manifolds For Stock Turbos

Couldn't load pickup availability

Need to share this part or send this to somebody? Click that little icon thingy for a quick link

This part number is designed for use with OE Turbos.

The Full-Race Formline Cast Stainless Exhaust Manifolds for the Gen 1 (2011-2016) Ford Ecoboost 3.5L engines are a direct replacement for the OEM cast iron exhaust manifolds. Due to some inherent flaws, the oem cast iron manifolds are known to warp or crack, resulting in costly repairs. Besides that, the oem cast iron manifolds don't flow very well and present fitment challenges when used with larger turbos. The full-race formline cast stainless manifolds solve these issues. Cast from 347 stainless steel, the formline manifolds resist warping and cracking . These manifolds are a 100% bolt-on replacement - including new OEM gaskets, studs and nuts.

For years 304 stainless steel has been a go-to material for sturdy, long lasting turbo manifolds and other motorsport exhaust components. It's known that Ford EcoBoost 3.5L owners push their engines hard and demand extreme reliability under grueling conditions - failure is not an option. That's why we’ve opted for an upgrade from 304 stainless steel to 347 stainless steel. 347 stainless is commonly found anywhere high temperature and highly corrosive environments exist - from refinery equipment to jet engine parts. This material maintains superior resistance to any type of failure under high temperature operating conditions.

Ford recently revised the OEM service replacement manifold to combat the warping issue by switching to stainless steel and adding additional mounting holes to the manifold flange to better secure the manifold to the cylinder head. Other aftermarket manifold manufacturers have added bolt holes, but the truth is the extra bolts are NOT the ideal solution to this issue, just the cheapest. The issue still comes down to the cast iron material used in the construction of the manifolds is not able to handle the 1050C / 1922F exhaust gas temps these engines generate.

Cast iron starts to fail at 1500F maximum temp but starts to warp much earlier than that, especially when the material is thin. Compare the thickness of the Formline manifold flanges to the OEM flange and the difference is clear. In addition to being 1/2" thick vs 3/8" thick, the Full-Race Formline Ecoboost manifold is cast from 347 stainless steel. This material is able to withstand temps of up to 950C / 1740F, making it ideal for an EcoBoost exhaust manifold.

INCREASED FLOW = MORE POWER

The OEM Ford Cast Iron Ecoboost exhaust manifolds don't flow very well due to some limitations in their design. Let's face it- the oem manifolds aren't designed for power. We've started with a clean-sheet design to ensure that the full-race formline cast stainless manifolds outflow all available manifolds. We've opened up the outlet port to closely match the inlet port on the exhaust side of the turbochargers. In addition, we've increased the diameter of the runners for maximum flow.

INCREASED FLOW CAPACITY

The OEM log manifold exhaust chamber is an incredibly small slot-shaped passage. It’s at its narrowest after the front two exhaust ports, right before the third. When this area is converted to an equivalent ‘hydraulic diameter’ it measures only 29 mm (1.14”). Ford expects two cylinders worth of exhaust flow to cram its way through that duct! For reference, that's smaller than the runner we would use for (1) cylinder on a 1.6 L Honda turbo manifold.

Another shortcoming of the OEM log manifold design is the mismatch between the 30mm manifold outlet and the 34.5mm turbocharger turbine inlet. The log manifold has a smaller outlet than the inlet of the turbine housing - meaning exhaust flow is forced to run into a sharp 90° step! This is the least efficient and most restrictive way of joining the flow of two dissimilar sized ducts.

We increased the manifold outlet from 30mm (1.18”) to 34.5mm (1.36”) to match the size of the entry to the turbine housing (also 34.5 mm). This small change translates into a 32% increase in outlet area. The next task was to give each cylinder a little bit more breathing room by increasing the runner cross section area. Our new runners start equalling the area of the exhaust ports, and gradually taper down to a minimum diameter of 30 mm (1.18”) each. Compared to the OEM measurement of 29 mm that may not sound like much but remember the Formline manifolds have a min diameter of 30 mm for EACH cylinder! All this will result in reduced backpressure and increased turbocharger efficiency